Our services

Our specialist contract packing and contract manufacturing services provide high quality, cost-effective support for dry food and general merchandise suppliers. Core services include bagging, flow-wrapping, cartoning, containers & tubs filling (multi-head weighing), hand-packing, prefill display and clip stripping, added-value & remedial work, and warehousing.

We also offer tailored packing solutions, and operate clean-room environments for handling nut-free, nut-trace and sensitive products. All of our automated, semi-automated and manual production lines are equipped with metal detection systems. Our reliability, flexibility, efficiency and customer support levels are second to none.

Bagging

We undertake many types of bagging operation to meet customers' precise requirements. With different clean room environments at our disposal, we cater for everything from allergen-free to temperature and humidity sensitive products. Our specialised automated bagging equipment includes Sandiacre LT320 Twin, NOVUS 350 Vertical and Doy Zip 380 VFFS machines.

Bagging options include:

- Pillow packs

- Pouches

- Doy bags

- Quad bags

- Block/flat bottom bags

- Gusset bags

- Zip closure packs

Our equipment includes a number of vertical form, fill and seal (VFFS) machines, fed from either multiple bucket elevators or multi-head weighers. These create bags and tubes from heat-sealable films – with variable bag sizes.

Flow-wrapping

Flow-wrapping – also known as horizontal form fill-and-seal wrapping – uses automatic machines to wrap product with film and seal it in one continuous operation.

We are experts in using both heat- and cold-seal films for packing food and other products. We use food-grade polypropylene, with a crimp-seal top and bottom and a fin/lap-seal along the length of the back of the pack. The entire range is covered – from single-unit packs to large multipacks. Our solutions are offered with or without film registration, allowing for printed, clear or opaque films.

Lines can be free-filled or pre-filled to a prescribed orientation, and can incorporate packs with backing or insert cards/trays. Our flow-wrapping machines are all equipped with date-coding systems for 'use by', 'best before', barcode, lot number and other individualised markings.

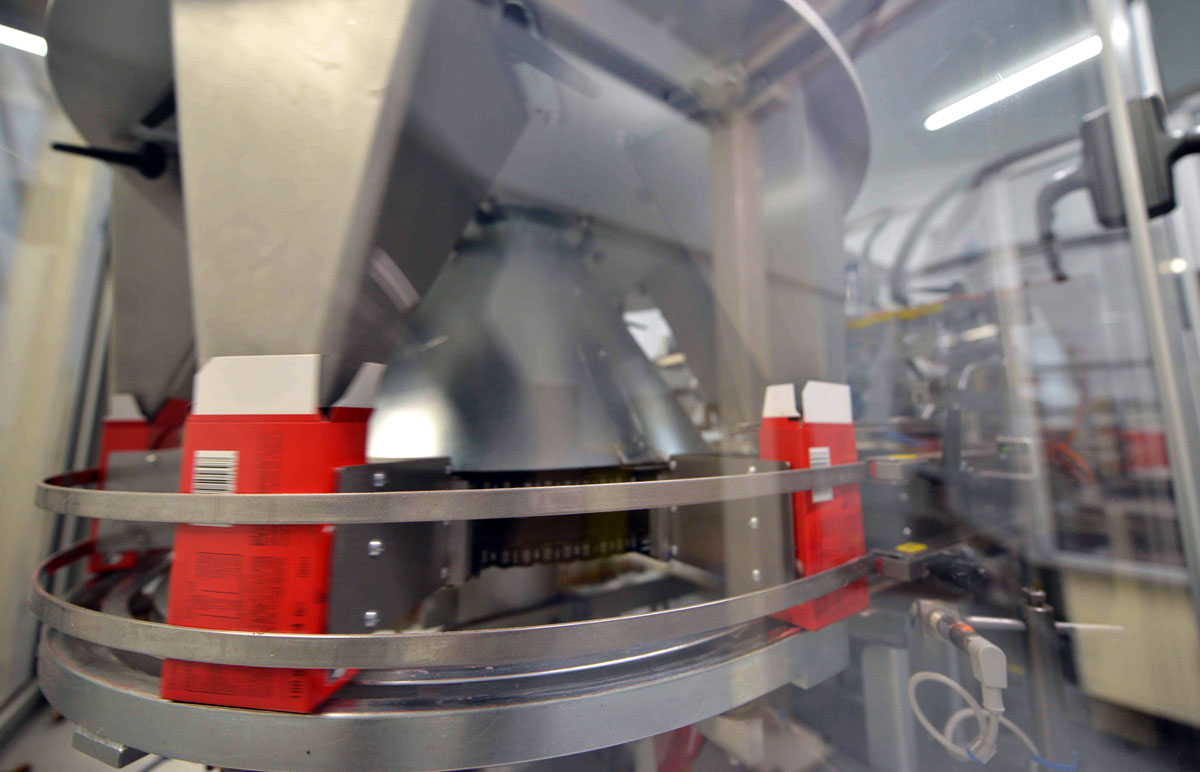

Cartoning

We operate both horizontal and vertical cartoning machines, including those with the capability of creating seasonal/Christmas selection boxes, biscuit boxes and tapered carton formats, among others.

Our automatic and semi-automatic cartoning machines offer high versatility and are capable of cartoning products of all shapes and sizes. They are efficient and cost-effective methods of assembling, filling and gluing cartons.

Our experienced teams will ensure your products are handled securely and with great care.

Containers & tubs filling (multi-head weighing)

In addition to our core bagging capabilities, we also fill pots, buckets, jars, tubs and other containers with product before sealing them. This work can be undertaken as a clean room activity where naked or primary wrap products are packed to a required recipe – either as single or multiple components.

We operate both fully automatic and semi-automatic dry product fill lines, capable of producing pots filled with single variant or random multi-product mixes.

Through our skilled operational teams and state-of-the-art multi-head weighing systems, we provide reliable and value-for-money packing services.

Hand-packing

As part of our wide range of packing solutions, we also offer the option of hand- or manual-packing. This is a very flexible approach to product packing, and we pack a huge variety of seasonal and other merchandise this way – including Covid-19 face masks (lower image).

We recommend hand-packing when either the packaging or the product configuration dictates, or when the product itself is not suited to mechanised fulfilment. For example, for friable biscuits we would normally weigh and fill tubs by hand.

Hand-packing by line can also be a cost-effective solution for packing small batches, where the cost of setting up a machine line would be prohibitive. It can also be a viable option for packing batches of product samples and new product ranges.

Prefill displays & clip stripping

The vital role packaging plays in capturing the attention of today's consumers means that its design must be eye-catching and innovative, as well as functional. This has increased demands on co-packers/co-manufacturers to create production lines that can accommodate these designs.

Our bespoke solutions include packing directly into counter display units (CDUs) and other stand-alone store displays of various shapes and sizes.

Clip strips are hard or flexible plastic strips on to which product is hung in vertical stacks for retail display and consumer purchase – and they are used to merchandise a wide range of products. They are an effective means of maximising impulse purchases without taking up valuable shelf space.

Added-value & remedial work

We offer a wide variety of added-value and remedial work services, including:

- Sourcing packaging materials for various customer products/projects

- Printing and applying labels – such as ingredients lists, barcodes, etc.

- Printing directly on to packaging – including 'sell by' and 'use by' dates, batch/lot codes, etc.

- Re-labelling – manual and automated

- Product/packaging inspection and QC

- Repair, rework and resorting product

- Packaging reconfiguration/re-packing

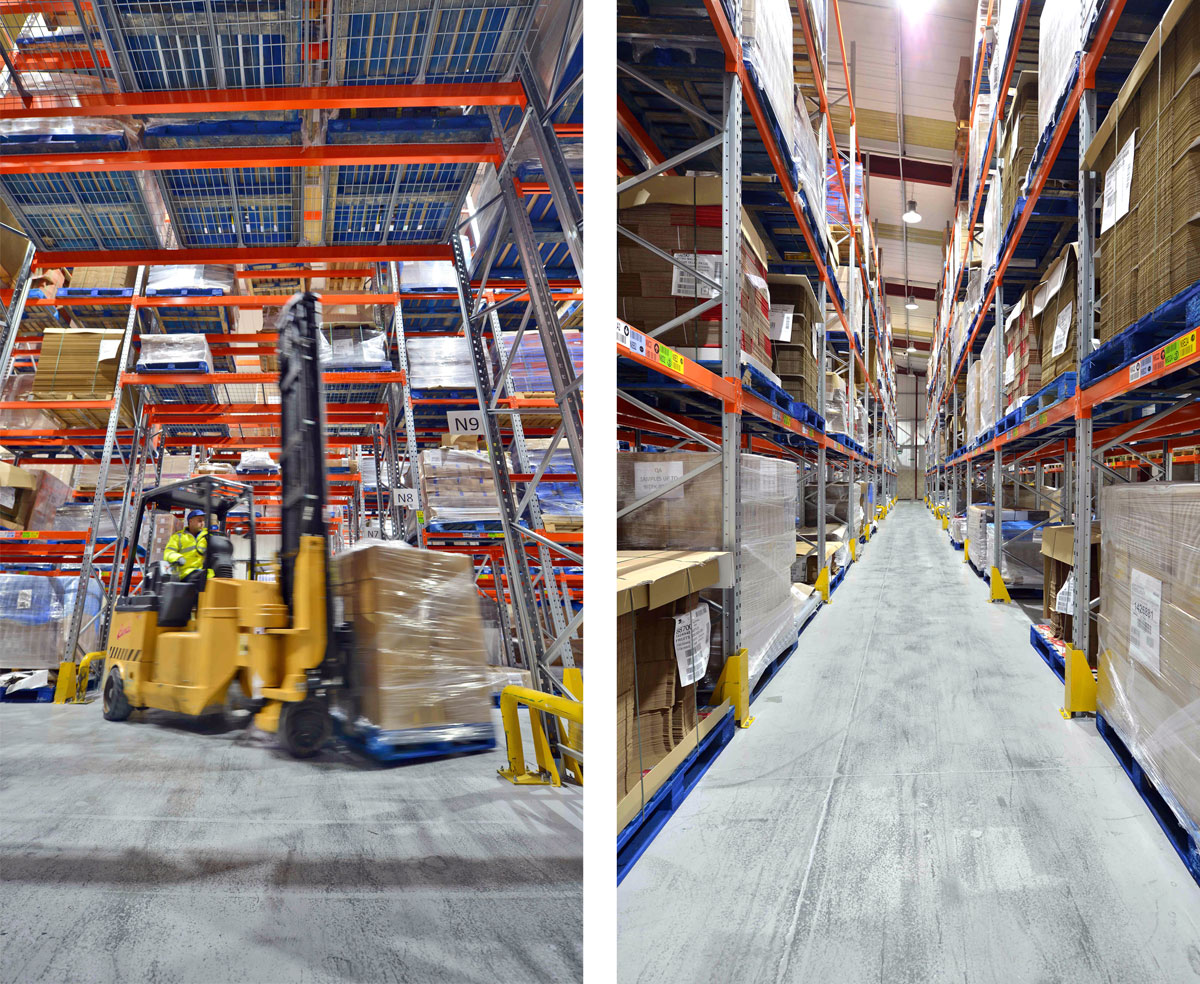

Warehousing

Our dedicated, fully racked and air-conditioned warehouses are integrated into our production facilities.

Generally operating on a pick, pack and despatch basis for quick turnaround, our warehousing enables clients to bulk-buy their packaging materials, supplies and consumables – reducing both purchase and transport costs.